|

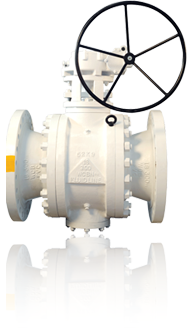

Ball Valves

A Ball Valve is a stop valve in which the closing member, the movable part to block the flow, is a spherical ball. Sometimes, the ball may be floating or mounted on trunnion support based on sizes and pressures. Spring-loaded.

Design Features: Regular Port, Full Bore, 2-piece or 3-piece design. Seats can be of PTFE NYLON, CARBON GRAPHITE etc. suitable for operating conditions. Ball components have a precise finish enabling a high number of valve operation cycle. Continuity between body and ball, ball and stem is provided by an antistatic device. The stem anti blow out design, is mechanically separated with the ball. In case of deterioration of the soft seat due to a prolonged exposure to a fire, a metal to metal contact, between seat and ball will restore the sealing to stop the flow of fluid.

Applications:

Petroleum, Power Generation, Chemicals, Fertilizers & Natural Gas / Fuel Oil Control

Operators: Lever Operated. : Gear, Electrical Actuator, Pneumatic / Hydraulic Actuator.

Special Features: Fire safe, Jacketed, Extended Stem.

Production Capacity: 1/2"-6" - 1400 Nos/Month, 8" & Above - 225 Nos/Month |

Material |

Size Range |

Construction |

ANSI Class |

Standard |

Cast Aloy Steel |

2" - 20" |

Bolted or Pressure Sealed |

150# - 2500# |

BS 5351 API 6D. |

Cast Stainless Steel |

2" - 20" |

Bolted or Pressure Sealed |

150# - 2500# |

|

Bronze |

2" - 6" |

Bolted Bonnet |

150# - 600# |

|

Temperature range: -20 to 180°C

Pressure Rating: Vacuum upto 621 BAR

End to End Dimension: API 6D/ANSI B16.10

Inspection Std.: API 598/BS 6755

Ends: Flanged End, Screwed Ends, Buttweld, Socket Weld

|